Привет боец. Надеюсь сюда ты пришел узнать азы азов пайки, скрутки и всего того что тебе предстоит только узнать и воплотить в жизни твоей любимой Honda Civic. Как вариант эта статья просто тебя обучит работе с паяльником и терминами. Во первых у тебя дома наверное найдется старый медный паяльник типа отвертка-лопата. Такая штука тебе может понадобится только при пайки проводов.

Для пайки на плате придется найти паяльник с узким жалом мощностью 30-45 ватт. Больше не нужно, меньше смысла нет. Всякое барахло лучше не брать, топами на рынке являются компании ERSA и Solomon, но для наших работ, кармана, и качества пойдет и отечественный паяльник Светозар.

Главное чтобы его жало крепилось болтом, обычно в наборе идет так же подставка, что очень помогает в работе. Естественно если будешь паять на улице или при ветре придется брать паяльник помощней, иначе вряд ли что получится. Перед началом конкретной работы, советую спаять из проволоки типовой кубик в 5см. Это простое занятие на 8 точек спайки.

Хороший пример мастер класса по пайке

Я не буду грузить вас нудной теорией которая есть после видео снизу, просто посмотрите это видео с комментариями тут

- Губкой для паяльника удалите избыток припоя с жала паяльника

- Далее демонстрация флюса, и процесс облуживания паяльника

- Очистим провода и не сильно скрутим каждую из частей

- Скручиваем провода именно друг на друга, типы скруток есть ниже в статье

- Капаем или мажем флюсом место пайки, больше флюса легче пайка!

- Плавим припой на жало и точным движением припой растекается по скрутке

- Во втором способе, нагреваем нужную точку спайки и к ней подносим припой

- Используем кембрик или термоусадочную трубку для изоляции

- Греем кембрик зажигалкой, феном, или паяльником не касаясь жалом, со всех сторон скрутки

Припой

Припой — металл или сплав, применяемый при пайке для соединения заготовок и имеющий температуру плавления ниже, чем соединяемые металлы. Является неким материалом типа клея для металла. Два кусочка металла, проволоки можно соединить между собой лишь расплавив каплю припоя. Припой расплавится быстрей если температура достаточная и имеется флюс.

Самый знаменитый припой в нашей стране это ПОС-61, что расшифровывается как Припой Оловянно Свинцовый, имеющий долю свинца 61 процента в составе. Сейчас с приятием анти-свинцовых природных законов, появилась без свинцовая пайка, на упаковке вы обязательно встретите надпись RoHC на зеленом фоне. Это означает что в пайке свинца нет, возможны другие компоненты например серебро. ПОС-61 имеет точку плавления в 190 градусах Цельсия, в то время как без свинцовые припои имеют точку плавления за 300 градусов, и более дорогую цену.

Флюс

Флюс — вещество или смесь органического и неорганического происхождения, предназначенное для удаления окислов(загрязнений) с поверхности под пайку, снижения поверхностного натяжения, улучшения растекания жидкого припоя и защиты от действия окружающей среды. Обеспечивает лучшую растекаемость припоя в плавком состояние. По сути убирает всю грязь под температурой, при смешивание с припоем придает ему более текучую характеристику.

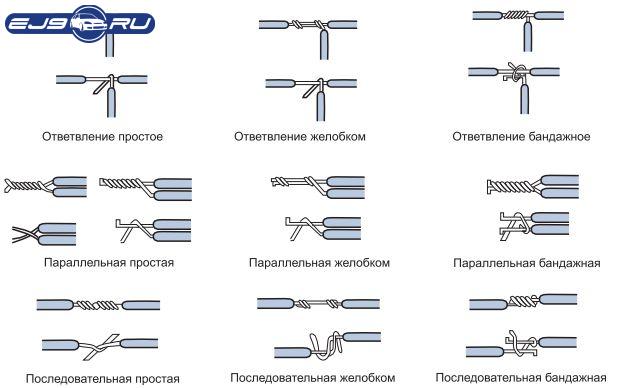

Типы скруток

Изоляция

Главное в изоляции, это скрыть оголенные участки проводов, а также волоски проводов от других проводов, или земли (массы, корпуса). Используйте кембрики изоленту. Старайтесь паять так чтобы кембрик одевался легко, без зазубрин. Иначе со временем зазубрина может прорваться. Не используйте по второму разу изоленту это плохой тон, да и качество низко. Не используйте так же скотч. Есть изоляционная лента, синяя или черная. Все.

Инструменты

Каждый мало мальский уважающий себя электрик должен обзавестись парой паяльников, для тонких работ и больших мощностей с подставкой. Кусачки они же бокорезы, должны справляться с откусываем миллиметровых ножек резисторов или проводов. Перочинный ножик для оголения проводов, а лучше скальпель. Используйте припой уже вместе с флюсом, не толще 1мм, и отдельный тюбик с флюсом.

Приобретите термоусадочные трубки в автомагазине, и там же спросите изоленту и пластиковые хомутики. Если работа ведется за столом найдите себе в помощь третью руку, в ней уже есть увеличительное стекло. Для удобства возьмите оплетку с флюсом, для отпайки.